Featured

Jesd22 Method Ja-104

Jesd22 Method Ja-104. Attachment method used should ensure that the entire mass of the sample(s) is reaching the temperature extremes and the soak requirements. | δc/c r | ≤ 10% of initial value 2.

Boardcom, alldatasheet, datasheet, datasheet search site for electronic components and semiconductors, integrated circuits, diodes, triacs and other semiconductors. 1.temperature:85±5 ℃ 2.time:1000 hours 1.no mechanical or electrical damage. Also used as preconditioning for other reliability tests.

Boardcom, Alldatasheet, Datasheet, Datasheet Search Site For Electronic Components And Semiconductors, Integrated Circuits, Diodes, Triacs And Other Semiconductors.

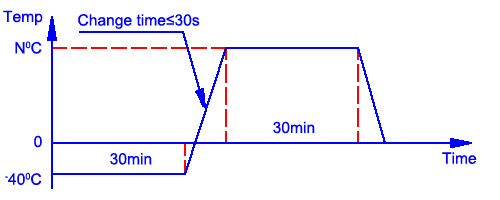

If stress exceed the limit stress, crack and rupture will be observed. A description is not available for this. Step2 :transition time 1min max.

Notice Jedec Standards And Publications Contain Materi Al That Has Been Prepared, Reviewed, And

To determine the ability of the part to withstand the customer's board mounting process; Jesd201 environmental requirements for tin whisker. If 85°c part or 105°c part the 1000 cycles will be at that temperature.

Verify Physical Dimensions To The Device Specification :

6 ( 1/1 page) manufacturer: | δc/c r | ≤ 10% of initial value 2. 40 °c upper test temperature:

This Standard Provides A Method For Determining Solid State Devices Capability To Withstand Extreme Temperature Cycling.

10ea x 3 lots : This standard provides a method for determining solid state devices capability to withstand extreme temperature cycling. This test is intended to determine the suitability of component parts for use in electronic equipment that may be subjected to moderately severe shocks as a result of suddenly applied forces or.

150 °C Number Of Cycles:

Data and is considered accurate at time of going to print. Largestload stillmeet specifiedtemperature cycling requirements thermocouples,per 3.3. Physicallytransfer loadfrom one temperature chamber other.load transfer applies triplechamber cycling.

Comments

Post a Comment